Max Ayliffe, Senior Geologist, Ernest Henry Mining Pty Ltd

Click here to download paper as PDF

Introduction

The development of the Ernest Henry Cu-Au deposit and details of the deposit geology have been well documented (Craske, 1995; Ryan, 1997; Crookes and Ryan, 1998). Recent work in the mine has generated a large new geological database from a number of different sources:

grade control logging, sampling and assaying;

blast hole logging, sampling and assaying;

concentrator throughput and recovery data;

blast hole penetration rate data;

geological and geotechnical mapping.

These new data are used for more than just conventional grade control activities, including:

rock/ore type characterisation;

predictor of concentrator throughput;

predictor of blast hole drilling rates;

determination of structural controls on the orebody.

This paper documents the compilation and current use of the new geology database and discusses how it has been invaluable in optimising both drill and blast fragmentation and metallurgical performance.

Data Collection

Grade control sampling at Ernest Henry is currently completed using 15 x 15 metre spaced reverse circulation drilling programs. Holes are usually drilled 48 metres deep or 3 benches. Rock chip samples are collected on two-metre intervals and geologically logged, and analysed for a suite of different elements (Cu, Au, As, Fe, Co, S, Mo, Ni).

Blast hole logging is a routine daily task undertaken by all geologists at Ernest Henry. All blast holes in ore and one in three blast holes in hard rock waste are logged to identify the various geological units. One in five blast holes in waste are also routinely sampled and analysed for acid waste rock characterisation and the standard geochemical suite.

The grade control and production blast hole chip logging is performed using a relatively simple alteration/breccia type logging scheme. The logging has identified 6 major rock types in the current Ernest Henry Pit (Figure 1). Major lithotypes include variably brecciated: felsic volcanics, mafic volcanics and clay altered volcanics. Examples of these different rock types are shown in Plates 1-6.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Plate 6. MV – Fine grained strongly foliated mafic volcanic/siltstone unit displaying intense biotite, carbonate with minor actinolite ± minor haematitic k-feldspar. This unit contains abundant pyrite and ± minor economic chalcopyrite mineralisation. |

Ore grade rock type relationships

Ore grades are strongly correlated to the rock type and particularly the matrix content of the ore. For example:

High-grade central core of the deposit (+1.2% Cu) is predominantly composed of FV2 matrix supported breccia (Plate 1 – FV2 ms).

Medium grade zone surrounding the central core (0.8-1.2% Cu) is composed of clast supported FV2 breccia (Plate 2 – FV2 cs).

Low grade ore (0.4-0.8% Cu) and the waste immediately surrounding the ore is predominantly composed of FV1 crackle breccia (Plate 3 – FV1).

Bulk waste on the eastern and western side of the orebody is predominantly massive intensely k-felspar altered FV.

Elongate zone in the centre of rock type distribution map is related to the massive low grade (0.5-0.9%Cu) mafic meta volcanic unit (Plate 4 – MMV).

Strongly supergene altered material in the southern region of stage 3 pit have variable grades (0.4-1.8% Cu), are clay altered volcaincs (Plate 5 – CAV).

Strongly foliated footwall mafic volcanics (Plate 6 – MV) exhibit minor low-grade mineralisation and composes the footwall of the deposit.

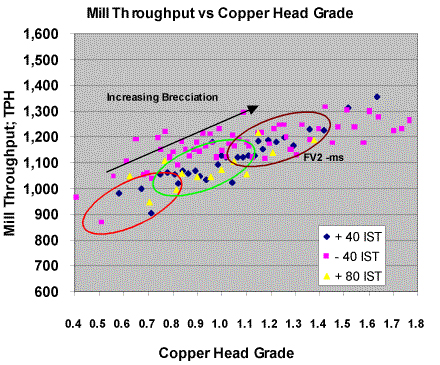

Concentrator Throughout

The relationship between rock breccia type and ore grade can be elaborated further by correlating the crusher feed grades to concentrator throughput, with ore grade being equivalent to degree of brecciation. Figure 2 demonstrates that there is a strong positive correlation between grade and concentrator throughput.

Figure 2. Plant throughput versus copper head grade

for all mineralisation types

Throughput however, is strongly influenced by the degree of weathering and supergene alteration. Figure 2 separates the concentrator ore feed into supergene, transitional and primary ore type categories. This shows that the supergene material has a significantly higher throughput compared to other ore types (approximately +100 tph). Due to the effect of supergene alteration on mill throughput, the grade, breccia type and throughput relationships were determined only for primary/transitional ore. The relationship between throughput, grade and breccia type, for primary/transitional felsic volcanic units are summarised in Table 1.

Table 1: Throughput, Grade, and Rock Type relationships for felsic rock types

|

|

% Cu |

|

|

|

|

|

|

|

|

|

|

|

|

|

The grade and throughput relationship for MV and MMV rock types are poorly defined, as these units make up less than 15% of the total ore feed. The MV and MMV units however, are usually low to medium grade (0.5-0.9% Cu) and generally have reduced throughputs similar to FV1 between 800-1000 tph.

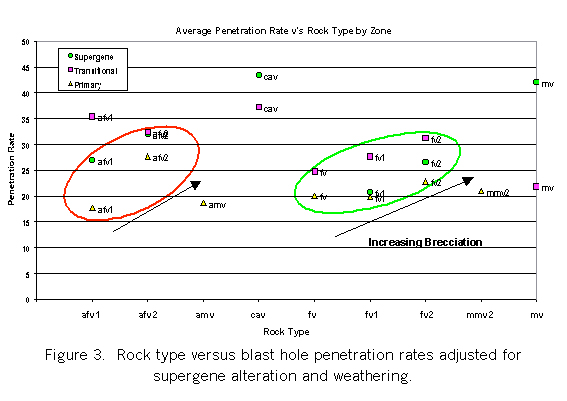

Blast Hole Penetration Rates

Analysis of the blast hole drilling penetration rate data from 2030 bench was performed to identify any correlation existing between blast hole penetration rate, rock breccia type and consequently plant throughput. Correlation between drilling penetration rates and rock types was performed by merging the penetration rate data with the blast hole geological logging for the 2030 bench. The data were sorted on rock type and graphs of rock types versus penetration rate generated (Figure 3).

Figure 3 demonstrates that drilling penetration rates are strongly effected by supergene alteration (see CAV). However, Figure 3 also shows that there is an underlying trend of increasing penetration rate with increasing proportion of brecciation and matrix content. This is true not only for unaltered felsic units (FV, FV1 and FV2) but also for altered felsic units (aFV, aFV1 and aFV2). The drill penetration rate versus rock type relationship for mv, amv and mmv2 units do not show a strong trend, due to the paucity of data.

Through the collection, correlation and use of grade, rock breccia type, drill penetration rates and plant throughput data, valuable predictive information is obtained for input into mine planning and concentrator optimisation. Concentrator optimisation is obtained by maintaining steady state conditions through blending of different ore types and hardness. Blast hole penetration rate modelling is an important parameter for drill production scheduling and optimisation of ore fragmentation. This discussion has demonstrated that grade, rock breccia type and drill penetration rate may be indicators of plant throughput. However, one of the major influencing factors on these parameters within the current Stage 3 pit, is secondary supergene alteration and weathering.

Control on Supergene Alteration

Supergene alteration at Ernest Henry is most strongly developed over the upper lens of the deposit and is controlled by major fault structures (Figure 4). Several major structures have been identified from resource definition drilling. Figure 4 clearly shows the control that some of the major structures have on clay/supergene alteration (Fault 4 & 2). Several other previously unidentified structures including the “NC Fault” have been identified and mapped within the current Stage 3 pit, also have strong control on supergene alteration.

Figure 4. Oblique N-S section of interpreted geology in the Stage 3 pit. Note two major structures Fault 2 & 4 confining the clay altered volcanic/supergene mineralisation.

Recently it has been observed that these structures are also controlling the mineralisation along the footwall of the upper lenes. Figure 4 also shows that to the north of Fault 4 the rocks are un-mineralised and relatively unaltered compared to highly supergene altered ore to the south. These structures are obviously having a major impact on the geometry and characteristics of the Ernest Henry orebody. The occurrence of post mineralisation structures bounding the ore suggest that further undefined fault displaced mineralisation may be present near the deposit.

It has also been observed that these major structures are controlling the Proterozoic ground water aquifers. Mapping and modelling of the faults has enabled these structures to be targeted and intersected by deep outer pit dewatering bores. The modelling, targeting and drilling of these major structures was the culmination of a number of months of geological data collection, interpretation and discussion. This demonstrates the value and importance of careful observation, collection, interpretation and modelling of production geology data.

Conclusions

Careful observation, collection and interpretation of a variety of geological data during production has enabled relationships between a number of physical parameters including: rock types, plant throughput, drill penetration rate and structure to be developed.

The relationship between rock/ore breccia type, grade, plant throughputs and drill penetration rates has been strongly overprinted and masked by secondary supergene alteration.

Supergene alteration has been strongly influenced by major structures identified within the orebody and current Stage 3 pit. These structures have greatly affected the distribution of rock types and mineralisation within the deposit and consequently mill throughputs, drill penetration rates and groundwater flows.

The occurrence of post mineralisation structures bounding the ore suggest that further undefined fault displaced mineralisation maybe discovered proximal to the deposit

Successful targeting of these water bearing structures is aiding pit dewatering and should have a major impact on reducing mining costs.

As mining progresses additional data collection and interpretation will improve the geological understanding of the Ernest Henry deposit and add further value to the project.

Acknowledgments

The author would like to thank colleagues in EHM Mine Technical Services Department for their constructive comments and contributions and Ernest Henry Mining Pty Ltd for kindly consenting to publication of this paper.

References

Craske, T.E., 1995. Geological Aspects of the Discovery of the Ernest Henry Copper deposit, Northwest Queensland. In: Recent Developments in Base Metal Geology and Exploration, Australian Institute of Geoscientist Bulletin 16:95-109.

Crookes, R.A. and Ryan, A.J., 1998. Evaluation of the Ernest Henry Cu-Au Deposit Mineral Deposit. In: Proceeding of Australasian Institute of Mining Metallurgy Annual Conference Mount Isa, Queensland. AusIMM 98 – “The Mining Cycle”:177-184.

Ryan, A.J., 1998. Ernest Henry Copper Gold Deposit. In: Geology of Australian and Papua New Guinean. Mineral Deposits, Eds: D.A. Berkman and D.H. Mackenzie. The Australasian Institute of Mining and Metallurgy:759-768.

Received: March 2000

Published: May 2000

AIG Journal Paper 2000-09 May 2000