Exploring In Queensland – An Overview

John Anderson, General Manager Exploration – Australia & Africa, MIM Exploration

Click here to download the paper as a PDF

Introduction

The year 2000 presents ongoing challenges to Queensland’s waning mineral exploration industry. Most are related to global or national conditions but some are specific to Queensland.

The challenges confront all participants including the un(der)-employed geoscientists and other staff affected by the halving of the State’s annual exploration expenditure since 1996; the teams retained to make new discoveries that have not been readily forthcoming since 1995, while managing ever-increasing land access restrictions and compliance requirements; the companies considering the value of exploration within their drive for cost efficiencies and shareholder value; and the Government in establishing an attractive framework for re-investment that will benefit the longer term health of the State.

Ore Type Characterisation at the Ernest Henry Cu-Au Mine

Max Ayliffe, Senior Geologist, Ernest Henry Mining Pty Ltd

Click here to download paper as PDF

Introduction

The development of the Ernest Henry Cu-Au deposit and details of the deposit geology have been well documented (Craske, 1995; Ryan, 1997; Crookes and Ryan, 1998). Recent work in the mine has generated a large new geological database from a number of different sources:

grade control logging, sampling and assaying;

blast hole logging, sampling and assaying;

concentrator throughput and recovery data;

blast hole penetration rate data;

geological and geotechnical mapping.

These new data are used for more than just conventional grade control activities, including:

rock/ore type characterisation;

predictor of concentrator throughput;

predictor of blast hole drilling rates;

determination of structural controls on the orebody.

This paper documents the compilation and current use of the new geology database and discusses how it has been invaluable in optimising both drill and blast fragmentation and metallurgical performance.

Data Collection

Grade control sampling at Ernest Henry is currently completed using 15 x 15 metre spaced reverse circulation drilling programs. Holes are usually drilled 48 metres deep or 3 benches. Rock chip samples are collected on two-metre intervals and geologically logged, and analysed for a suite of different elements (Cu, Au, As, Fe, Co, S, Mo, Ni).

Blast hole logging is a routine daily task undertaken by all geologists at Ernest Henry. All blast holes in ore and one in three blast holes in hard rock waste are logged to identify the various geological units. One in five blast holes in waste are also routinely sampled and analysed for acid waste rock characterisation and the standard geochemical suite.

The grade control and production blast hole chip logging is performed using a relatively simple alteration/breccia type logging scheme. The logging has identified 6 major rock types in the current Ernest Henry Pit (Figure 1). Major lithotypes include variably brecciated: felsic volcanics, mafic volcanics and clay altered volcanics. Examples of these different rock types are shown in Plates 1-6.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Plate 6. MV – Fine grained strongly foliated mafic volcanic/siltstone unit displaying intense biotite, carbonate with minor actinolite ± minor haematitic k-feldspar. This unit contains abundant pyrite and ± minor economic chalcopyrite mineralisation. |

Ore grade rock type relationships

Ore grades are strongly correlated to the rock type and particularly the matrix content of the ore. For example:

High-grade central core of the deposit (+1.2% Cu) is predominantly composed of FV2 matrix supported breccia (Plate 1 – FV2 ms).

Medium grade zone surrounding the central core (0.8-1.2% Cu) is composed of clast supported FV2 breccia (Plate 2 – FV2 cs).

Low grade ore (0.4-0.8% Cu) and the waste immediately surrounding the ore is predominantly composed of FV1 crackle breccia (Plate 3 – FV1).

Bulk waste on the eastern and western side of the orebody is predominantly massive intensely k-felspar altered FV.

Elongate zone in the centre of rock type distribution map is related to the massive low grade (0.5-0.9%Cu) mafic meta volcanic unit (Plate 4 – MMV).

Strongly supergene altered material in the southern region of stage 3 pit have variable grades (0.4-1.8% Cu), are clay altered volcaincs (Plate 5 – CAV).

Strongly foliated footwall mafic volcanics (Plate 6 – MV) exhibit minor low-grade mineralisation and composes the footwall of the deposit.

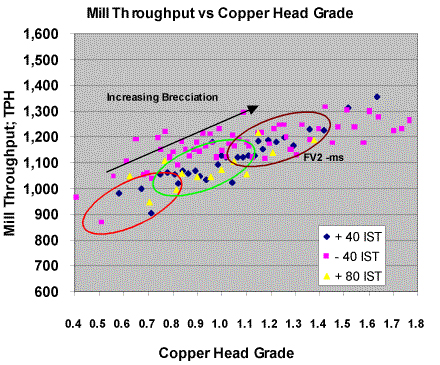

Concentrator Throughout

The relationship between rock breccia type and ore grade can be elaborated further by correlating the crusher feed grades to concentrator throughput, with ore grade being equivalent to degree of brecciation. Figure 2 demonstrates that there is a strong positive correlation between grade and concentrator throughput.

Figure 2. Plant throughput versus copper head grade

for all mineralisation types

Throughput however, is strongly influenced by the degree of weathering and supergene alteration. Figure 2 separates the concentrator ore feed into supergene, transitional and primary ore type categories. This shows that the supergene material has a significantly higher throughput compared to other ore types (approximately +100 tph). Due to the effect of supergene alteration on mill throughput, the grade, breccia type and throughput relationships were determined only for primary/transitional ore. The relationship between throughput, grade and breccia type, for primary/transitional felsic volcanic units are summarised in Table 1.

Table 1: Throughput, Grade, and Rock Type relationships for felsic rock types

|

|

% Cu |

|

|

|

|

|

|

|

|

|

|

|

|

|

The grade and throughput relationship for MV and MMV rock types are poorly defined, as these units make up less than 15% of the total ore feed. The MV and MMV units however, are usually low to medium grade (0.5-0.9% Cu) and generally have reduced throughputs similar to FV1 between 800-1000 tph.

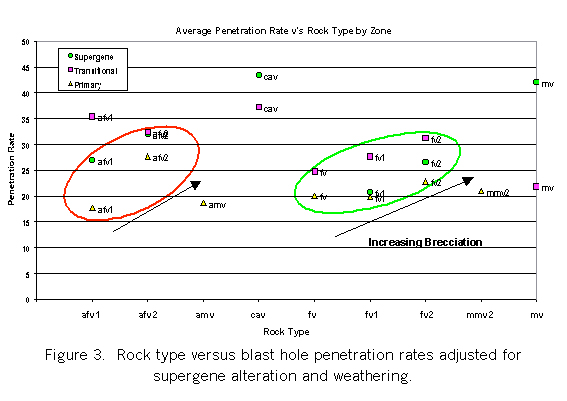

Blast Hole Penetration Rates

Analysis of the blast hole drilling penetration rate data from 2030 bench was performed to identify any correlation existing between blast hole penetration rate, rock breccia type and consequently plant throughput. Correlation between drilling penetration rates and rock types was performed by merging the penetration rate data with the blast hole geological logging for the 2030 bench. The data were sorted on rock type and graphs of rock types versus penetration rate generated (Figure 3).

Figure 3 demonstrates that drilling penetration rates are strongly effected by supergene alteration (see CAV). However, Figure 3 also shows that there is an underlying trend of increasing penetration rate with increasing proportion of brecciation and matrix content. This is true not only for unaltered felsic units (FV, FV1 and FV2) but also for altered felsic units (aFV, aFV1 and aFV2). The drill penetration rate versus rock type relationship for mv, amv and mmv2 units do not show a strong trend, due to the paucity of data.

Through the collection, correlation and use of grade, rock breccia type, drill penetration rates and plant throughput data, valuable predictive information is obtained for input into mine planning and concentrator optimisation. Concentrator optimisation is obtained by maintaining steady state conditions through blending of different ore types and hardness. Blast hole penetration rate modelling is an important parameter for drill production scheduling and optimisation of ore fragmentation. This discussion has demonstrated that grade, rock breccia type and drill penetration rate may be indicators of plant throughput. However, one of the major influencing factors on these parameters within the current Stage 3 pit, is secondary supergene alteration and weathering.

Control on Supergene Alteration

Supergene alteration at Ernest Henry is most strongly developed over the upper lens of the deposit and is controlled by major fault structures (Figure 4). Several major structures have been identified from resource definition drilling. Figure 4 clearly shows the control that some of the major structures have on clay/supergene alteration (Fault 4 & 2). Several other previously unidentified structures including the “NC Fault” have been identified and mapped within the current Stage 3 pit, also have strong control on supergene alteration.

Figure 4. Oblique N-S section of interpreted geology in the Stage 3 pit. Note two major structures Fault 2 & 4 confining the clay altered volcanic/supergene mineralisation.

Recently it has been observed that these structures are also controlling the mineralisation along the footwall of the upper lenes. Figure 4 also shows that to the north of Fault 4 the rocks are un-mineralised and relatively unaltered compared to highly supergene altered ore to the south. These structures are obviously having a major impact on the geometry and characteristics of the Ernest Henry orebody. The occurrence of post mineralisation structures bounding the ore suggest that further undefined fault displaced mineralisation may be present near the deposit.

It has also been observed that these major structures are controlling the Proterozoic ground water aquifers. Mapping and modelling of the faults has enabled these structures to be targeted and intersected by deep outer pit dewatering bores. The modelling, targeting and drilling of these major structures was the culmination of a number of months of geological data collection, interpretation and discussion. This demonstrates the value and importance of careful observation, collection, interpretation and modelling of production geology data.

Conclusions

Careful observation, collection and interpretation of a variety of geological data during production has enabled relationships between a number of physical parameters including: rock types, plant throughput, drill penetration rate and structure to be developed.

The relationship between rock/ore breccia type, grade, plant throughputs and drill penetration rates has been strongly overprinted and masked by secondary supergene alteration.

Supergene alteration has been strongly influenced by major structures identified within the orebody and current Stage 3 pit. These structures have greatly affected the distribution of rock types and mineralisation within the deposit and consequently mill throughputs, drill penetration rates and groundwater flows.

The occurrence of post mineralisation structures bounding the ore suggest that further undefined fault displaced mineralisation maybe discovered proximal to the deposit

Successful targeting of these water bearing structures is aiding pit dewatering and should have a major impact on reducing mining costs.

As mining progresses additional data collection and interpretation will improve the geological understanding of the Ernest Henry deposit and add further value to the project.

Acknowledgments

The author would like to thank colleagues in EHM Mine Technical Services Department for their constructive comments and contributions and Ernest Henry Mining Pty Ltd for kindly consenting to publication of this paper.

References

Craske, T.E., 1995. Geological Aspects of the Discovery of the Ernest Henry Copper deposit, Northwest Queensland. In: Recent Developments in Base Metal Geology and Exploration, Australian Institute of Geoscientist Bulletin 16:95-109.

Crookes, R.A. and Ryan, A.J., 1998. Evaluation of the Ernest Henry Cu-Au Deposit Mineral Deposit. In: Proceeding of Australasian Institute of Mining Metallurgy Annual Conference Mount Isa, Queensland. AusIMM 98 – “The Mining Cycle”:177-184.

Ryan, A.J., 1998. Ernest Henry Copper Gold Deposit. In: Geology of Australian and Papua New Guinean. Mineral Deposits, Eds: D.A. Berkman and D.H. Mackenzie. The Australasian Institute of Mining and Metallurgy:759-768.

Received: March 2000

Published: May 2000

AIG Journal Paper 2000-09 May 2000

Vera South: Discovery History

Ian Butler, Tim Murphy and Jennifer Parks, Normandy Pajingo Pty Ltd

Introduction

The Pajingo Project consists of several economic gold-silver orebodies. They include the mined out Scott and Cindy Lodes, the Vera–Nancy deposits which are presently being mined, and the recently discovered Vera South deposit. The project is located 150 km south-southwest of Townsville and 80 km by road south of Charters Towers in north Queensland (Figure 1).

Figure 1. Location and geological plan of Pajingo orebodies

and location of Figures 4 and 5.

The Project operates as a 50:50 joint venture between Normandy Pajingo Pty Ltd (wholly owned subsidiary of Normandy Mining Ltd) and Battle Mountain (Australia) Inc. (wholly owned subsidiary of Battle Mountain Gold Company).

Normandy is the operations manager and assumed management of exploration in March 1998. The Joint Venture is presently proceeding with development of the Vera South resource as part of a A$48 million expansion project which will result in doubling the annual gold production to more than 200,000 ounces per annum.

The purpose of this paper is to outline the geology of Vera South, and the use of geophysics in its discovery beneath younger Tertiary and Quaternary cover. A comparison is also made with the Vera-Nancy deposits immediately along strike, as a guide to future exploration in the field.

History

The Pajingo Epithermal System (PES) was discovered by Battle Mountain in 1983 and is presently interpreted to cover an area of 150 km2 (Richards et al, 1997). The Scott Lode was discovered in 1984, and mined from mid 1987 until the end of 1993.

Battle Mountain actively explored the region until 1991 for additional shallow open pittable resources without success. ACM Gold Operations Pty Ltd (later absorbed into Normandy Operations Pty Ltd) farmed in to earn a 50% interest in the Pajingo Project in early 1991. Normandy managed exploration until 1995 with the main focus being large tonnage low grade gold mineralisation similar to Mt Leyshon. Battle Mountain recommenced exploring for open pittable resources in 1994 under a Mill Feed Agreement with Normandy (Kay and McKay, 1997) following the development of a small resource at Cindy.

In late 1994 the economic potential at Vera North was recognized, and 12 months later the Vera North orebody was discovered at depths greater than 250 m below the surface. An aggressive drilling campaign followed and outlined several discrete pods of mineralisation on the Vera-Nancy structure by early 1997. A total of 3.1 million tonnes at 14.0 g/t gold, for 1.4 million ounces, were outlined (Figure 2) and mining commenced in late 1996 (Evans and Jones, 1997; Kay and McKay, 1997).

Figure 2. Longitudinal projection (looking NE) of the Nancy North, Nancy, Vera North and Vera South orebodies showing metal content contours in gram-metres,

Geology

Regional Setting

The geology and mineralisation of the Vera-Nancy orebodies has been described previously (Evans and Jones, 1997; Richards et al, 1997), and is summarised as follows. The PES is located at the northern margin of the Devonian to Carboniferous Drummond Basin, which is interpreted to be a back-arc extensional basin. The Pajingo orebodies discovered to date are low sulphidation quartz-adularia epithermal vein type with bonanza gold and silver mineralisation. Past production plus identified resources for the field total 6.2 million tonnes at 13.0 g/t gold, for 2.6 million ounces.

Cover Rocks and Regolith

Tertiary sediments of the Southern Cross and Campaspe Formations, and later Quaternary deposits, cover approximately 80% of the PES. The thickness (maximum 90 m) of these overlying younger sediments varies rapidly over short distances due to deposition on an incised topographic surface. There is a well-developed and lateritic weathering profile up to 120 m depth from surface.

Epithermal Gold Mineralisation

The vein deposits are structurally controlled with several different orientations, however most of the mineralisation is located within the northwest trending Vera-Nancy structural corridor (Figure 1). Vera South is located within the southeasterly extension of this structure.

The epithermal gold mineralisation is located within quartz veins hosted by proximal andesitic volcanic rocks. The mineralisation at Scott Lode has been dated as Middle Carboniferous (342 Ma; Perkins, 1993). The veins occur as discrete steeply plunging ore shoots with short strike lengths developed in dilational positions within the Vera-Nancy structural corridor (Figures 2 and 3). The fault geometry and the interplay of crosscutting and/or splay faults controls these sites. They occur over a strike length of 2.1 km and the main structure can be confidently interpreted over a strike length of 6 km.

Figure 3. Cross Section – Vera South

The mineralised lodes are generally narrow (1 to 10 m) and vertically extensive. The gold is fine-grained (5 to 150 microns) and mostly occurs as electrum within epithermal textured quartz veins or breccia containing quartz fragments/matrix. Mineralised quartz veins have a close spatial association with multiphase and overprinting hydrothermal breccias.

Alteration assemblages spatially associated with the vein mineralisation are complex with evidence of overprinting events. A halo of phyllic alteration (silica-pyrite-sericite/illite) is developed up to 50 m from the host structure with silica-pyrite most intense adjacent to the quartz veining. Distally there is widespread propylitic alteration. Kaolinite and/or illite–smectite alteration commonly overprints the phyllic alteration.

Comparison between Vera-Nancy and Vera South

In many respects the geology and mineralisation at Vera South are similar to that at Vera-Nancy, with some notable differences as outlined in Table 1.

Table 1. Geological Characteristics: Comparison between Vera-Nancy and Vera South

|

Geology

|

|

|

|

Tertiary |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Vera South Discovery

The Vera South orebodies are located from 200 m to 800 m southeast along strike from the Vera Pit (Figures 4 and 5) beneath up to 40 m of younger cover. The area was first targeted at the end of 1996 during systematic exploration along the Vera-Nancy structural corridor. It was initially not interpreted to be highly prospective because gradient array resistivity data from a regional survey, so helpful elsewhere in outlining the position of the Vera-Nancy structure, showed a low order response and it was orientated east-west rather than northeast-southwest (Figure 4). Surface geochemistry is not an effective tool for delineating targets at Pajingo because of the Tertiary sediments, which cover the mineralisation and contain clasts of auriferous epithermal quartz which can lead to surface gold anomalies up to 1 km from source.

As there is no outcrop, interpretation of the resistivity (Figure 4) and airborne magnetic data guided the initial drilling. The first 20 drill holes were drilled due north in order to test this interpreted east-west orientation. The results were mixed, with several structures intersected; some with bonanza intercepts, however correlation between holes was tenuous. A detailed gradient array survey oriented in a northeast-southwest direction was completed in early 1997 and this revealed that the interpreted east-west structure was more likely to be an artefact of line spacing and survey orientation. Subtle northwest-southeast trends could be recognized in the data (Figure 5) and this supported the possibility that mineralised structures were oriented in this same direction.

Drilling recommenced with holes directed to the northeast. Again the results were mixed. As it eventuated, these holes unfortunately managed to intersect both the “gap” between the V1 and V2 lodes, and barren quartz in V3. Drilling at Vera South was then suspended to enable a geological re-interpretation. The Battle Mountain site exploration team was convinced after their experience at Vera-Nancy that Vera South remained prospective, but the drilling to date indicated the prospect had limited size potential.

Drilling recommenced in late 1997. The five holes in this programme intersected significant mineralisation in what are now referred to as V1 and V2. Further holes drilled in March 1998 following the wet season provided more ore grade intercepts, and confirmed the economic potential of the resource. Resource extension drilling has continued since then by testing potentially mineralised areas based on a continually evolving model rather than a strict grid pattern. By June 30th 1999 the inferred resource at Vera South had grown to 2.0 million tonnes at 14.1 g/t gold for 889 000 oz gold at a total discovery cost of $5.47 per ounce.

Exploration Methodology

The key exploration tools used for the Vera South discovery proved to be drilling and to a lesser extent geophysics. Detailed airborne magnetics, which delineates structural trends defined by magnetite destruction, and gradient array resistivity surveys (Figures 4 and 5), which can detect silicified structures through up to 50 m of cover, were used. These methods only provided a guide and could not be used to reliably plan drill holes. Since the discovery, other geophysical methods have been trialed over Vera South, including CSAMT and TDEM. Neither has proved to be cost effective and/or useful.

Figure 4. Gradient array resistivity contours from regional survey with lines oriented True North showing mineralised structures at 1200 RL, outcrop, and location of cross-section in Figure 3.

Figure 5. Gradient array resistivity contours from detailed survey with lines oriented Grid North showing mineralised structures at 1200 RL, outcrop, and location of cross-section in Figure 3.

The only surface geochemical method trialed has been MMI, however the results to date have been difficult to interpret.

Conclusions

The Vera South resource was finally recognized after 12 months of persistent exploration by the site team, and 28 drill holes. Earlier discovery was thwarted by thick cover, which effectively masked the geological, geophysical and geochemical expression of the orebody. Based on experience gained from previous exploration in the vein field, the sporadic bonanza intersections coupled with intense alteration and major structures provided the exploration team with the confidence to persevere with drilling at Vera South.

The Vera South mineralisation has not been fully closed off, and it is clear that the Vera-Nancy structural corridor and other structures in the vein field are still highly prospective. The exploration history of Vera South confirms that epithermal quartz vein style gold and silver deposits are not easy to find, especially under cover, and a considerable amount of detailed exploration, particularly drilling is required. Pajingo ore is high grade, has favourable metallurgical properties and delivers low cost ounces, making it a particularly attractive target at current gold price levels.

Acknowledgements

The authors gratefully acknowledge the permission of Normandy Pajingo Ltd and Battle Mountain Gold Company to publish this information and thank the many staff members and consultants who have contributed to the exploration and development of the Pajingo Project.

References

Evans, R.C., and Jones, B.H., 1997. The discovery and evaluation of the Vera-Nancy Deposit, North Queensland. World Gold ’97 Conference Proceedings. The Australasian Institute of Mining and Metallurgy:233-237.

Kay, B. and McKay K., 1997. Vera-Nancy Gold Discovery: Not Just Geology. New Generation Gold Mines, Case Histories of Discovery. Australian Mineral Foundation:1.1-1.5.

Perkins, C., 1993. Isotopic Dating of Precious and Base Metal Deposits and their Host Rocks in Eastern Australia. Final Report April 1993, AMIRA Project P334.

Richards, D.R., Elliott, G.J. and Jones, B.H., 1998. Vera North and Nancy gold deposits, Pajingo. In: Geology of Australian and Papua New Guinean Mineral Deposits, Eds: D.A. Berkman and D.H. Mackenzie. The Australasian Institute of Mining and Metallurgy, Melbourne:685-690.

Received: March 2000

Published: May 2000

AIG Journal Paper 2000-10, May 2000

Julia Creek Vanadium and Oil Shale Deposit

Simon Coxhell and Barry Fehlberg, Fimiston Mining NL

Click here to download paper as PDF

Introduction

The Julia Creek Vanadium Project is centred 15 km east of the township of Julia Creek in north-west Queensland, and 165 km east of the mining province of Mt Isa-Cloncurry, on the Julia Creek 1:250,000 mapsheet (SF1403; Figure 1).

Figure 1. Location of the Julia Creek project area.

Figure 1. Location of the Julia Creek project area.

The project lies within St Elmo Pastoral Station and EPM 12862-12864, which covers areas previously explored for oil shale by CSR Limited between 1968-1988, Placer Exploration between 1988-1991, and CRA between 1991-1994.

The deposit is 100% owned by Fimiston Mining NL. Fimiston acquired the project in October 1998 after research suggested the opportunity to locate and develop a large oxide vanadium project in the upper oxide zone where the oil shale has been leached of the oil. Drilling and assaying work completed since then has established one of the world’s largest vanadium resources. Leaching has resulted in the enrichment of vanadium mineralisation in the top 15m, and improved mining and beneficiation characteristics of the orebody.

A detailed program of metallurgical testing has established a method for the beneficiation, leaching and purification of vanadium products from the oxidised oil shale. Current work is being directed at reducing reagent consumption in an effort to lower the projected operating and capital costs of the project.

The fresh oil shale below 15 m vertical depth contains in excess of three billion barrels of oil, located between 20 and 40 m vertical depth over an area of 600 km2. With the rise in the oil price the potential for the joint extraction of both the vanadium and the oil within the fresh oil shale offers scope to significantly increase the value of the project.

Exploration and Development History

Exploration centred on Julia Creek over the last thirty years has been extensive and widespread, with a significant proportion of the work focused on the search for, and development of, the oil shale within the unoxidised kerogen-rich oil shale and limestone layers.

Mineral tenements were originally pegged by Aquitane in 1968 in the general area of Julia Creek. The initial exploration target was sedimentary uranium in the Cretaceous Toolebuc Formation, but the program was unsuccessful.

The exploration focus shifted to the oil and vanadium within the Toolebuc Formation and a joint venture was formed with The Oil Shale Corporation (TOSCO). Through 1969 the TOSCO – Aquitane J.V drilled 55 holes on roughly a six km grid east and west from Julia Creek. This work outlined a remarkably consistent mineralised horizon and preliminary mining and processing studies for a proposed oil shale and vanadium project were undertaken (Whitcher, 1992).

Between 1970 and 1973 research was undertaken into vanadium extraction and marketing with a number of potential metallurgical options being tested in laboratory work in the USA.

A rise in the oil price in 1973 prompted work directed at investigating the feasibility of oil extraction from the fresh rock. Extensive drilling was completed throughout the area with a large oil shale deposit of fairly uniform grade (65-75 litres per tonne) located along the west flank of the St Elmo Structure adjacent to the St Elmo Homestead.

A number of different sized projects were reviewed and a range of processing and refining options were considered.

In 1979 a significant rise in the oil price prompted renewed enthusiasm for the development of a large-scale oil shale project at Julia Creek. In excess of 250 exploration holes were drilled on the western flank of the St Elmo Structure in the vicinity of St Elmo Homestead and resource estimation completed based on the detailed drilling.

In 1982 the detailed drilling defined an oil shale resource proposed to be mined by shallow open cut means. The unoxidised oil shale resource of 1,798 Mt was estimated to average 63.5 litres per tonne of oil and 0.35% V2O5 per tonne of ore (Whitcher, 1992).

Additional test work and pilot plant studies to investigate oil shale extraction technologies were instigated following advances in retorting technologies. A significant amount of research was completed by CSIRO in association with CSR Ltd.

By 1982, progressive expenditure on the Julia Creek project had reached $15 million and it was concluded that the required selling price for oil was US$42/barrel for the project to be economically viable (Herbert, 1980). Between 1983 and 1988, CSR’s activities continued to advance technological research into aspects of oil shale processing before they withdrew from the oil shale project in 1988. Placer acquired the ground in 1988 and completed a review of the data. They withdrew in 1991.

CRA acquired the tenements in 1991 and focused attention on the extraction of oil from the oil shale. They drilled a number of holes and completed some metallurgical work in their in-house laboratory. An extensive review of previous work was completed and data compilation was carried out. CRA withdrew from the project in 1994 after concluding that the production of oil from the Julia Creek deposit was uneconomic at the oil price of the day.

Prospector Wayne Jones applied for new mineral tenements in July 1996 and Fimiston entered into an agreement to acquire the Julia Creek tenements from Jones in October 1998.

Regional Geology

The Julia Creek oil and vanadium rich shale is located within marine sediments of the Early Cretaceous Toolebuc Formation, a stratigraphic unit that occurs throughout the Eromanga Basin in central-northern Queensland.

The Eromanga Basin is a sub basin of the Great Artesian Basin and consists of a number of thick sequences of non-marine and marine sedimentary units. The Toolebuc is part of the Rolling Downs Group of the Eromanga Basin that covers a wide but relatively shallow structural depression in eastern Australia, covering 1.5 million km2. The basin was developed as a major downwarp on a basement of Proterozoic to Palaeozoic metamorphic and igneous rocks during the Jurassic to Cretaceous.

Exon and Senior (1976) have proposed an evolutionary history of the basin. Sedimentation in the Eromanga commenced in the early Jurassic period, with the deposition of fluvial sandstones of the Hutton Formation as a consequence of downwarping of the basement. These non-marine Jurassic sandstones are the main aquifers of the Great Artesian basin.

Further fluviatile, lacustrine, and possibly deltaic sedimentation, continued at the close of the Jurassic. A worldwide marine transgression during the Cretaceous period (Schlanger and Jenkyns, 1986) was marked in the Eromanga Basin by the deposition of shallow marine and paralic sediments, including the Toolebuc Formation. Following final withdrawal of the sea, lithic sediments were deposited above the Toolebuc Formation. The stratigraphy of the Eromanga Basin is described in detail by Exon and Senior (1976).

The Toolebuc Formation is a flat lying early Cretaceous (Albian ~ 100 My) sediment that consists predominantly of black carbonaceous and bituminous shale and minor siltstone, with limestone lenses and coquinites (mixed limestone and clays). It is composed of two distinct units representing two different facies: an upper coarse limestone-rich-clay-oil shale unit (coquina) and a lower fine grained carbonate-clay-oil shale unit.

The Toolebuc Formation outcrops only at the margins of the Eromanga and Carpentaria basins. At Julia Creek it is draped over an original basement high and has been structurally brought to the surface. Where the unit outcrops it forms low, rubbly, subtle topographic highs which have been the source of road building materials in many areas.

A buried basement ridge, the St Elmo Structure, trends in a north-north-west direction from the Julia Creek Project area. Outcropping Toolebuc Formation is found over a wide area elongated in a north-north-west orientation in this area.

The limestone within the Toolebuc Formation has an abundant fossil assemblage which has been extensively studied. Two main faunal assemblages have been recognised, corresponding to the upper coquina facies (shelly limestone and clay) and a lower fine grained carbonate shale facies.

Local Geology

In the vicinity of St Elmo Station outcrops of both the upper coquina and lower oil shale of the Toolebuc Formation are strongly oxidised to approximately 15 m deep (Figure 2).

Figure 2. Plan showing the outcropping area of the Toolebuc formation, and a cross section through the ore body showing the depth of weathering and the units making up the ore body.

Figure 2. Plan showing the outcropping area of the Toolebuc formation, and a cross section through the ore body showing the depth of weathering and the units making up the ore body.

The upper coquina averages 5 to 6 m thick, and is composed of alternate layers of coarse shelly limestone and oxidised fine grained material identical to the lower shale unit. The limestone layers within the coquina comprise single and multiple laminae of crystalline calcite derived dominantly from shells of the fossil bivalves Inoceramus and Aucellina. Alternate layered individual limestone and clay horizons within the coquina are from 1 to 10cm thick. Bands of goethite (1-2 cm thick), derived from oxidised pyrite rich sediments within the Toolebuc, comprise approximately 5% of the rock mass. Average grain size of the coquina ranges from 200 mm plates of calcite, to fine clays and coccoliths between 0.5-10 microns. The clay rich layers within the coquina increase in abundance and thickness towards the base, reflecting alternating and changing environmental conditions.

The lower unit is the main oil shale horizon which, in the fresh rock, contains the majority of the oil. This fine grained oil shale averages 7 m thick and is principally composed of calcite, clays and kerogen. Pyritic sediments (1-2 cm thick) comprise approximately 5% of the rock mass. Oil grade within the fresh rock varies from 55 to 100 litres per tonne and averages between 65 and 75 litres per tonne. The oil is contained within the kerogen, which comprises approximately 18wt% of the fresh oil shale. The composition of the kerogen is about 75% carbon, 8% hydrogen, 5% sulphur, 2% nitrogen and 10% oxygen (Tolmie, 1987).

The organic matter in the fresh shale is predominantly lamellar and referred to by Hutton et al (1980) as ‘lamosite’ (lamellar oil shale). The organic compounds are described as Alginite B in order to distinguish them from the more generally recognised Alginite A, in which clear evidence of algal morphology can be observed. Alginite B comprises elongate anastomosing films derived from benthonic algae that are referable to the Cyanophyceae genera of blue-green algae (Ozimic, 1986).

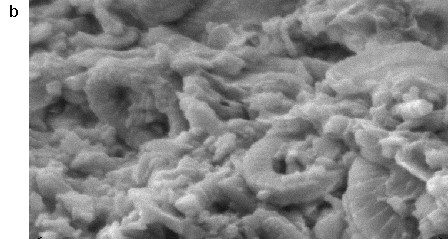

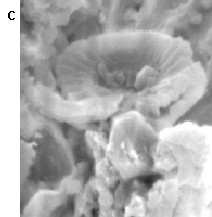

High magnification scanning electron microscopy reveals the oil shale contains abundant micro fossils, dominated by small planktonic foraminifera and coccoliths (algal plates) believed to be derived from Cyanophta / blue- green algae. Average grain size of the lower oil shale calcareous nanofossils and clays are less than 5 to7 microns (Figure 3).

Figure 3. Scanning electron microscope images of the Toolebuc shale, showing: (a) a foram test rimmed by crystals (probably calcite) and hosted in a matrix of coccoliths and clays, and (b) & (c) the morphology and size of the coccoliths (Camuti, 1999). Width of images: a: 50 microns, b: 14.5 microns, c: 7 microns.

Figure 3. Scanning electron microscope images of the Toolebuc shale, showing: (a) a foram test rimmed by crystals (probably calcite) and hosted in a matrix of coccoliths and clays, and (b) & (c) the morphology and size of the coccoliths (Camuti, 1999). Width of images: a: 50 microns, b: 14.5 microns, c: 7 microns.

The blue-green algae are interpreted to have formed extensive algal mats on the sea floor. The preservation of dead algal matter can be related to an oxidising-reducing boundary probably situated immediately below the base of the living algal mat layer and keeping pace with its upward growth. The clays and kerogen are derived from planktonic algae and blue-green benthonic algae (Glikson and Taylor, 1986) with the calcite representing the inorganic component of the organisms.

The episode of clear water calcareous sedimentation represented by the Toolebuc Formation ended when muddy conditions returned, preventing further growth of the benthonic fauna and leading to widespread deposition of the argillaceous sediments of the Allaru Mudstone (Ramsden, 1983).

Subsequent history of the basin has involved weathering, erosion and some tilting. Narrow north-west trending subvertical faults have been observed in the road quarries east of Julia Creek and are parallel to the broad trend of the Toolebuc outcrop and St Elmo structure. Deep weathering during the Tertiary resulted in oxidation to greater than 30 m locally, and averaging 15 m in the vicinity of Julia Creek.

In situ moisture content of the Julia Creek oil shale is estimated to be about 6 %.

Mineralogy of the Toolebuc Formation

Mineralogical work completed by Fimiston and others has established that the oil shale is principally composed of calcite, kerogen, quartz, kaolinite, smectite and pyrite. Minor minerals identified include mixed layered clays and gypsum. Trace minerals identified include sphalerite, chalcopyrite and galena.

In the oxide zone the kerogen and pyrite are completely oxidised. The kerogen appears to break down into amorphous oxide wad, while the pyrite forms goethite and hematite.

Within open pits near Julia Creek, which have been the source of road building material, tyayamunite, a calcium-uranium-vanadium oxide mineral has been found, in a rare occurrence.

The Toolebuc is anomalous in a wide range of elements including copper, zinc, nickel and molybdenum, and typical analyses of the oxidised oil shale and soft oxide coquina are presented in Table 2.

Table 2. Typical analyses of the oxidised Coquina and Oil Shale.

|

|

Oxide Coquine |

Oxide Oil Shale |

|

CaCO3 |

85% |

40% |

|

SiO2 |

10% |

35% |

|

Al2O3 |

1% |

7% |

Fe

|

0.75% |

3% |

|

S |

0.30% |

2% |

|

TiO2 |

0.06% |

0.30% |

|

V |

1400ppm |

2250ppm |

|

Mo |

100ppm |

300ppm |

|

Zn |

400ppm |

1100ppm |

|

Cu |

100ppm |

200ppm |

|

Ni |

100ppm |

300ppm |

|

U |

20ppm |

35ppm |

|

Ag |

1ppm |

2ppm |

|

Au |

10ppb |

15ppb |

|

Pt |

2ppb |

4ppb |

|

Pd |

2ppb |

4ppb |

Vanadium Mineralogy

The occurrence of vanadium in both weathered and fresh oil shale samples has been investigated in a number of past studies. Norrish and Patterson (1976) concluded that the vanadium in oil shale at Julia Creek is associated with mixed layered clays and contains approximately 60% of the vanadium present in the fresh oil shale. The other 40% occurs within silicates, pyrite and organic compounds.

Mixed layer clays isolated from weathered and unweathered oil shale contain 5-10% V2O5; vanadium substitutes in the octahedral positions of the clay structures to give an idealised formula of K(Al,V,Mg)4 Si7Al2O20(OH)4 (Patterson, 1994).

High levels of organically bound vanadium have been found at Julia Creek with one sample of fresh oil shale containing about half its vanadium chemically bound within the kerogen in the form of vanadyl porphyrins (Riley and Saxby, 1982). The remainder of the vanadium is found either within the mixed layered clays (illite-smectite), or associated with pyrite in the fresh material and goethite within the oxidised material.

Riley and Saxby (1982) investigated the different forms of vanadium based on the quantities that could be extracted by different acids. They found that vanadium occurred in a variety of forms including:

- species soluble in hydrochloric acid, (probably hydrated oxides and vandates adsorbed on clays or precipitated in the limestone);

- species soluble in hydrofluoric acid (probably vanadium silicates within clays or micas); and

- organically bound vanadium.

Weathering processes have destroyed the vanadyl porphyrin structures in the kerogen, releasing vanadium from the organic matter (Riley and Saxby, 1982). This weathering is thought to result in the transfer of hydrated oxides of vanadium into the clay structures.

Laterally continuous pyritic bands present within the Toolebuc Formation have been oxidised during weathering resulting in higher grade goethite bands which, in the coquina, can contain grades of up to 0.5% V2O5. It is suggested that the oxidation of pyrite in the Toolebuc created an acidic environment that enhanced the release of vanadium from the various mineral species (particularly the kerogen and pyritic zones), resulting in some mobilisation and enrichment of grades associated with the oxide zones.

Mineral associations of vanadium within the soft oxide coquina and the underlying oxidised oil shale have been examined in SEM studies commissioned by Fimiston. The vanadium was found to be associated with hydrated iron or iron/titanium oxides and mixed clays. The grade of the vanadium in the particles of hydrated iron oxides is about three times higher than that in the clays. However, the volume proportion of the clay-like phase is considerably higher (Burger et al., 1999).

Vanadium was also found in another mineral phase – wad. Wad is an amorphous mixture of various oxides, mainly of manganese, cobalt, iron and copper, with 10 to 20% water. The vanadium content in wad is approximately equivalent to that in hydrated Fe/Ti oxides.

The Depositional Environment and Mechanism of Vanadium Concentration

The vanadium within the Toolebuc Formation is interpreted to have been concentrated by marine organisms, fixing the vanadium from seawater over a long period of time in an anaerobic environment. The vanadium occurs as both organic and inorganic forms suggesting a unique combination of physical and chemical conditions was necessary for the accumulation of the various vanadium mineral species.

The fossil assemblage and mineralogy of the two main facies of the Toolebuc Formation provide important clues to the depositional environment and possible mechanism for the fixing of the vanadium.

The difference between the upper coquina and lower fine grained oil shale is related to the amount of oxygen present during deposition, and the possible depth of formation. The lower fine grained oil shale represents a reducing environment, while the upper laminated coquina represents fluctuating and progressively increased levels of oxygen in the sea suitable for the establishment of specialised low oxygen tolerant large sized benthonic shelly fauna (Ozimic, 1986). Possible fluctuation in the sea level (and/or in the physio-chemical conditions at the sea floor) sometimes favoured oil shale accumulation, but increasingly favoured formation of the coquina (Ramsden, 1986).

The close spaced and alternating sequence of the upper coquina shelly layers and the coquina and fine grained oil shale suggests periodic and cyclic changes to the anaerobic-aerobic boundary.

Ozimic (1986) has extensively studied the Toolebuc Formation and has proposed a quiet anaerobic deep water environment of deposition for the fine grained oil shale. The fine grained laminated nature of the oil shale suggests deposition under moderately deep conditions below the depth at which wave action is capable of stirring up the ine sediment. Correlation with modern oceans suggest a depth of approximately 200 m (Ramsden, 1980).

An analogy has been made between the white chalks characteristic of the Cretaceous in western Europe and North America, and the Toolebuc Formation, in that both consist of algal plates (coccoliths) and foraminifera. However, unlike the oxidising conditions that prevailed during the formation of the white chalk, the conditions at Julia Creek (and elsewhere within the Eromanga basin) were anoxic. As a consequence, not only was there an accumulation of very fine algal plates, but much of the associated organic matter was also preserved.

The abundance of planktonic foraminifera and coccolith remains in the oil shales suggests a productive oxygenated upper water layer in the environment of deposition (Glikson and Taylor, 1986).

The presence of pyrite, both as framboidal and massive bands throughout the organic calcareous complex, and within the foraminifera shells, indicates anoxic conditions at the water-sediment interface and possibly above it (Sherwood and Cook, 1986). The anaerobic environment would have enhanced growth of the cyanobacterial community as well as preservation of the organic matter following death of the organisms (Sherwood and Cook, 1986).

Reducing conditions under anoxic water make some toxic metals, for example lead, available for chelation with organic matter (Damison and Moore, 1986). Sediments deposited under anoxic marine waters contain abnormally high concentrations of uranium, copper, molybdenum, nickel, phosphorous and sulphur, which tend to correlate with organic carbon concentration (Schlanger and Jenkyns, 1986).

The uranium within the Toolebuc was interpreted by Ozimic to have probably been transported into the depositional area in a soluble hexavalent state by run-off waters from adjacent land masses, and reduced at the sea floor by organic matter to the insoluble tetravalent precipitate. A similar mechanism for the transport and reduction of vanadium is proposed.

A close association between calcite and organic compounds has been observed at Julia Creek during studies of the organic matter by Sherwood and Cook (1986). Calcareous outlines or replicas of microorganisms closely resembling cyanobacteria of Oscillatoria were observed. It was interpreted that calcite precipitation occurred upon the death of organisms as a result of excretion of amino acids by decomposing cyanobacteria. Bacterial decomposition of amino acids under anaerobic conditions in sediments can lead to an accumulation of ammonia, raising the pH, and bringing about the precipitation of calcium carbonate (Glikson and Taylor, 1986). The abundance of pyrite also points to anaerobic conditions and sulphate reduction processes.

The close association between vanadium mineralisation and organic and inorganic mineral species suggests the fixing of the vanadium during these periodic pH and chemical changes at the seafloor.

The environment of deposition envisaged for the formation and preservation of the Toolebuc Formation was a “positive water balance basin” (Damison and Moore, 1980) in which saline water entered from the north and circulated, while fresh water from the hinterland flowed northwards out of the region. The sea was most likely stratified with a permanent halocline below a layer of fresh water.

The conditions which favoured oil-shale deposition within the Toolebuc Formation were apparently terminated during the Cretaceous with the return of normal marine conditions. This was probably the result of an increase in saltwater inflow arising from a rising sea level and possible variations in conditions limiting the productivity in the euphotic zone (Ozimic, 1992).

Resource Estimates

Oil Shale

The Julia Creek oil shale deposit covers a vast area of the Eromanga Basin and, at a low cut off grade (+20 litres/tonne), would comprise a huge resource. The prospective oil shale horizon has been estimated to cover in excess of 500,000 square km (Exon and Senior, 1976) with an average thickness of 5-15 m. On this basis, and assuming an average thickness of 7 m and an average grade of 60 litres/tonne, the formation contains 2400 billion barrels of oil. A large proportion of this is covered by 100 to 1000 m of younger sediments.

It is in the vicinity of Julia Creek that the prospective horizon outcrops, and substantial resources are present near the surface (<40 m vertical depth) and mineable from an open pit mining operation with an acceptable strip ratio. The top 15 m has been weathered and the kerogen-oil content of the oil shale is depleted but, below the base of oxidation, the near surface oil shale deposit grades up to 90 litres per tonne and averages about 65-75 litres per tonne.

CSR Ltd undertook detailed studies into the viability of the project from the late seventies until 1988. Based on 1-2 km spaced drill holes they calculated an in situ resource of 4,252 million tonnes grading 62.8 litres per tonne (40 litre/tonne cut off) for 1.7 billion barrels of oil. A mining study based on the in situ resource and following additional drilling estimated total tonnage in three open pits at 1798 Mt at an average grade of 74 litres/tonne in the proposed southern pit, 67 litres/tonne in the central pit, 63 litres/tonne in the northern pit. An average strip ratio of 1:3.5 was estimated.

Vanadium Resource

Within the total Toolebuc Formation very large quantities of vanadium are present, with an estimated total global resource in excess of ten billion tonnes of vanadium. Work by Fimiston on the vanadium mineralisation within the Toolebuc Formation, near St Elmo Station, has indicated large tonnages of near surface oxidised vanadium mineralisation are located within both the upper coquina and lower oil shale. Similar vanadium contents have also been recorded in the fresh rock. Oxide vanadium resources within the Julia Creek Project area have been estimated at 340 Mt at 0.33% V2O5.

The estimated vanadium resource is composed of two principal ore types: the upper soft oxide coquina and the lower fine grained oil shale. The upper soft oxide coquina totals 160 mt @ 0.25% V2O5, and the lower fine grained oil shale totals 180 mt @ 0.40% V2O5.

Development

Fimiston’s work has focussed on the extraction of the vanadium from the upper portion of the formation, within 15 m of the surface. Near surface, the rocks are strongly weathered with oxidation enriching the vanadium values and, more importantly, rendering the upper soft oxide coquina friable and easy to mine and beneficiate.

Metallurgical testwork has shown that the coquina ore averaging 0.25% V2O5 can be readily and efficiently beneficiated to a 1.4% V2O5 concentrate via wet scrubbing, trommelling and cycloning. Coarse shelly limestone, containing negligible vanadium and comprising up to 85% of the total mass, is removed by this process leaving a fine grained clay and iron oxide product (<10 microns) containing 85-90 % of the original vanadium.

Due to the very fine grained nature of the fine calcareous microfossils in the underlying oil shale this material cannot be beneficiated using conventional cyclone technology. The microfossils, which contain negligible vanadium, cannot be readily separated from the fine clays and iron oxides.

A large number of leach tests at a range of temperatures and pressures have been completed on the 1.4% beneficiated coquina concentrate to determine an optimum method for the leaching of the clays and iron oxides. This testwork has shown that both alkaline and acid leaching can be used to solubilise the vanadium from the clays and iron oxides within the concentrate. Acid is more effective than alkali leach methods at lower temperatures, however the excessive acid consumption due to the high levels of calcite renders the process uneconomic. Results from alkaline leaching, using a combination of sodium carbonate and caustic soda at 250 °C, have been promising, with recoveries of greater than 75% achieved.

The main hurdle to development is the high consumption of the principal reagent, sodium carbonate. Stoichiometrically, the vanadium in the concentrate requires only one tenth of the sodium carbonate that is being consumed, however the formation of a sodium rich zeolite (analcime) in the autoclave is consuming any free sodium. This results in excessive reagent consumption. Current metallurgical activities are being directed at trying to prevent the formation of the analcime, and investigating the possible joint extraction of oil and vanadium from the fresh rock.

Conclusions and Further Work

On the basis of the significant potential of the Julia Creek deposit further work is required to assess its viability. The huge scale of the project and the potential for metallurgical breakthroughs that could alter the project parameters and economics suggest that further work is clearly justified.

An active work program to re-examine the various options for the development of a large scale oil shale deposit project at Julia Creek is now warranted. In particular, the suitability of new advances in process technology (such as that being used at Stuart Oil shale deposit) should be assessed in detail. Operating costs at Stuart are forecast at under $US10/barrel and if achievable will lead to a long term and profitable mining operation.

Similar operating costs may be achievable at Julia Creek and, coupled with income from vanadium which could be produced as a byproduct, project economics would be highly attractive.

Acknowledgments

The authors would like to thank Fimiston Mining N.L for permission to publish this paper.

References and Bibliography

Atkins, A.R., Fookes, C.J.R., Muradian, A. and Stephenson, L., 1986. Upgrading strategies for Julia Creek shale oil. Proceedings of the Third Australian Workshop on Oil Shale, Lucas Heights, 15-16 May 1986. CSIRO Division of Energy Chemistry:229-234.

Burger, R., Streltsova, N. and Angove, J., 1999. Vanadium extraction from the Julia Creek Deposit. Oretest Pty Ltd, Internal Company Report to Fimiston Mining N.L.

Camuti, K.S., 1999. Mineralogical Report: 11 Samples – Julia Creek Project. Lantana Exploration Pty Ltd, Internal Company Report FM9801 to Fimiston Mining N.L.

Dale, L.S. and Fardy, J.J., 1983. Trace Element characterization of Australian oil shales. Proceedings of the First Australian Workshop on Oil Shale, Lucas Heights, 18-19 May 1983. AAEC Lucas Heights Research Laboratories:57-60.

Damison, G.J. and Moore, G.T, 1980. Anoxic environments and oil source bed genesis. American Assoc. Pet. Geol. Bull, Vol 64:1179-1209.

Day, R.W., 1983. Geology and potential development of Queensland oil shales. Queensland Government Mining Journal, 84(986):463-470.

Exon, N.F and Senior, B.R, 1976. The Cretaceous of the Eromanga and Surat Basins. BMR Journal of Australian Geology and Geophysics, Vol 1:33-50.

Fookes, C.J.R., Atkins, A.R. and Walters, C.K., 1987. Characterization of nickel and vanadium in Australian oil shales and shale oils. Proceedings of the Fourth Australian Workshop on Oil Shale, Brisbane, 3-4 December 1987. CSIRO Division of Energy Chemistry:287-292.

Glikson, M. and Taylor, G.H,. 1986. Cyanobacterial mats: major contributors to the organic matter in Toolebuc Formation oil shales. In: Contributions to the Geology and Hydrocarbon Potential of the Eromanga Basin, Eds: D.I. Gravestock, P.S. Moore and G.M. Pitt. Geological Society of Australia Special Publication No 12:273-286.

Herbert, E.F., 1980. The shale oil alternative. In: Fuels for the Future. Ed. F. Colyer. Australian Institute of Petroleum 1980 Congress on the Future of Petroleum in the Pacific Region:35-42.

Hoffman, K.L., 1985. A palaeoenvironmental study of the northern reaches of the Toolebuc formation. Unpublished Honours Thesis, James Cook University.

Hutton, A.C. Kantsler, A.J., Cook, A.C. and McKirdy, D.M., 1980. Organic matter in oil shales. A.P.E.A. Journal, 20(1):44-67.

Hutton, A.C., Korth, J., Ellis, J., Crisp, P. and Saxby, J.D., 1987. Comparative study of Australian oil shales. Twentieth Oil Shale Symposium Proceedings, Ed: J.H. Gary. Golden, Colorado, 21-22 April 1987, Colorado School of Mines:10-23.

Matheson, S.G., 1991. An overview of oil shale resources and exploration in Queensland. Proceedings of the Sixth Australian Workshop on Oil Shale, St Lucia, Brisbane, 5-6 December 1991. Brisbane, University of Queensland:19-24.

Matheson, S.G., 1992. Queensland mineral commodity report: oil shale. Queensland Government Mining Journal, Vol 93(1082):18-27.

Norrish, K. and Patterson, J.H., 1976. Characteristisation of vanadiferous clays, Julia Creek. Abstracts, 25th Geological Congress, Sydney. Geological Society of Australia, 3:756-757.

Ozimic, S., 1986. The geology and petrophysics of the Toolebuc Formation and its time equivalents, Eromanga and Carpentaria Basins. In: Contributions to the Geology and Hydrocarbon Potential of the Eromanga Basin. Eds: D.I. Gravestock, P.S. Moore and G.M. Pitt. Geological Society of Australia Special Publication No 12:119-137.

Ozimic, S., 1992. Depositional Environment of the oil shale bearing Cretaceous Toolebuc Formation and its equivalents, Eromanga basin, Australia.

Patterson, J.H, Fuel, 1994. A review of the effects of minerals in processing of Australian shales. Fuel, 73(3):321-327.

Patterson, J.H., Ramsden, A.R, Dale and L.S, Fardy, J.J, 1986. Geochemistry and mineralogical residences of trace elements in oil shales from Julia Creek, Queensland, Australia. Chemical Geology, Vol 55:1-16.

Ramsden, A.R., 1980. Geochemistry, mineralogy and petrology of the type section of the Toolebuc Formation in BMR Boulia 3A stratigraphic drill hole. Aust CSIRO Inst. Earth Res. Restrict. Invest. Rep. 1197R.

Ramsden, A.R., 1983. Microscopic petrography of oil shales at Julia creek, northwestern Queensland. Journal Geological Society of Australia, 30:17-23.

Raphael, N. M. and Saxby, J.D., 1980.Australian oil shale deposits: a review. Investigation Report. CSIRO Institute of Earth Resources, 134.

Riley, K.W. and Saxby, J.D., 1982. Organic matter and vanadium in the Toolebuc Formation of the Eromanga Basin. Eromanga Basin Symposium, Summary Papers, compiled by P S Moore and T J Mount, Adelaide, 9-11 November 1982. Petroleum Exploration Society of Australia and the Geological Society of Australia:204-214.

Saxby, J.D., 1983. The distribution, properties and potential of Toolebuc oil shale. Proceedings of the First Australian Workshop on Oil Shale, Lucas Heights, 18-19 May 1983. AAEC Lucas Heights Research Laboratories:43-46.

Saxby, J.D. and Sato,S., 1989. Pyrolysis of oil shale/lignite mixtures. Is this a viable option for Australian Tertiary shales? Proceedings of the Fifth Australian Workshop on Oil shale, Lucas Heights, 6-7 December 1989. CSIRO Division of Fuel Technology:117-122.

Schafer, H.N.S., 1983. Flash pyrolysis of Rundle, Julia Creek and Condor oil shales. Proceedings of the First Australian Workshop on Oil Shale, Lucas Heights, 18-19 May 1983. AAEC Lucas Heights Research Laboratories:109-112.

Schlanger, S.O. and Jenkyns, H.C., 1976. Cretaceous oceanic anoxic events: causes and consequences. Geologie En Mijnbouw, Vol 55 (3-4):179-184.

Sherwood, N.R and Cook, A.C, 1986. Organic matter in the Toolebuc Formation. In: Contributions to the Geology and Hydrocarbon Potential of the Eromanga Basin. Eds: D.I. Gravestock, P.S. Moore and G.M. Pitt. Geological Society of Australia Special Publication No 12:255-265.

Sitnai, O., 1983. A process concept for Julia Creek oil shale retorting. Proceedings of the First Australian Workshop on Oil Shale, Lucas Heights, 18-19 May 1983. AAEC Lucas Heights Research Laboratories:97-100.

Smart, J. and Senior B.R. Jurassic-Cretaceous Basins of Northeastern Australia. Southern Pacific Petroleum N.L, 1998. Annual Report.

Southern Pacific Petroleum N.L, Central Pacific Minerals N.L. April, 1996. Wilson HTM, Brokers Review and Report.

Stephenson, L.C., Fookes, C.J.R., Atkins, A. R. and Muradian, A., 1987. Upgrading strategies for Julia Creek shale oil – part 2. Proceedings of the Fourth Australian Workshop on Oil Shale, Brisbane, 3-4 December 1987. CSIRO Division of Energy Chemistry:245-250.

Thomas, G., 1992. Julia Creek 2 – Report on exploration activities during the first year of tenure 26.11.91 to 25.11.92. CRA Exploration Pty Ltd. Queensland Department of Minerals and Energy Company Report CR 24923.

Thomas, G., 1992. Julia Creek 3 – Report on exploration activities during the first year of tenure 26.11.91 to 25.11.92. CRA Exploration Pty Ltd. Queensland Department of Minerals and Energy Company Report CR 24925.

Thomas, G., 1992. Julia Creek 4 – Report on exploration activities during the first year of tenure 5.12.91 to 4.12.92. CRA Exploration Pty Ltd. Queensland Department of Minerals and Energy Company Report CR 24926.

Thomas, G., 1992. Julia Creek 5 – Report on exploration activities during the first year of tenure 15.1.92 to 14.1.93. CRA Exploration Pty Ltd. Queensland Department of Minerals and Energy Company Report CR 24924.

Tolmie, D.B., 1984. Status of Julia Creek shale oil project. Proceedings of the Second Australian Workshop on Oil Shale, Brisbane, 6-7 December 1984. CSIRO Division of Energy Chemistry:20-24.

Tolmie, D.B., 1987. The status of the Julia Creek Project. Proceedings of the Fourth Australian Workshop on Oil Shale, Brisbane, 3-4 December 1987. CSIRO Division of Energy Chemistry:8-11.

Whitcher, I.G., 1993. A chronological resume of exploration and technological research conducted on the Julia Creek oil shale deposit northwest Queensland between 1967 and 1988. In: CR24927A, CRA Exploration Final QLD Mines Dept Report, G. Thomas and J. Shirley.

Received: March 2000

Published: May 2000

AIG Journal Paper 2000-11, May 2000

The Diamantina Hinge Zone – Exploration Folly or a Major New Base Metals Province South of Mt Isa?

Tony Alston, Exploration Director, Glengarry Resources NL

Click here to download paper as PDF

Glengarry Resources NL has applied for some 42,000 sq km of ground centred on the town of Bedourie, located about 350 km south of Mt Isa in western Queensland. The Project has been named the Diamantina Hinge Zone because of the interpreted intersection of two major intracontinental structures, i.e. the ESE trending Tran Tanami/Arunta Structure and the NE trending Diamantina Orogen. This hinge zone terminates the southern end of the Proterozoic Mt Isa Block and is considered to be very prospective for the discovery of major polymetallic deposits. (more…)