Anthony M Hespe, Western Metals Ltd

Click here to download paper as PDF

Introduction

Gunpowder– now called Mount Gordon – will be a familiar name to those who have worked in the mining industry in Queensland. It has a history of intermittent copper production, attempts at novel treatment processes and periods of closure dating back to the 1920s. Recent developments in geology, exploration and production, which have transformed the economics of the deposit, are the subject of this presentation.

Location and Ownership

The Mt Gordon Cu Mine is located 130 road km north of Mount Isa, Queensland at latitude 19°o 20’ S, longitude 139° 22’ E on the Camooweal (SE 54-13) 1:250,000 scale map sheet. The Mount Gordon Operation is owned by Western Metals Ltd.

Current Production and Resources/Reserves

Current ore production is from an open cut on the Esperanza ore body at a maximum rate of 750,000 tpa. All previous production was from an underground mine on the Mammoth ore body. Production from Mammoth is suspended and will resume as mining at Esperanza is completed.

Ore is processed through a novel autoclave leach process to produce 45,000 tpa of cathode copper by SX/EW.

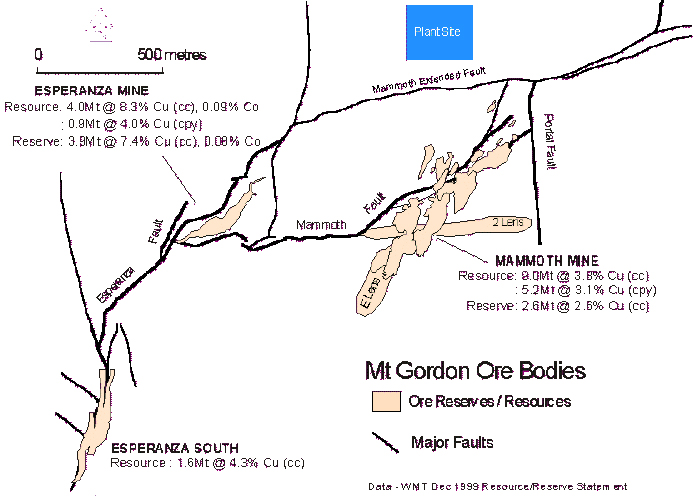

Resources/reserves at 31 December 1999 are shown in Figure 1. Reserves at Esperanza are sufficient for an 8-year mine life with a further 2 years reserves at Mammoth. Resources should extend the life of the operation to 15 years.

Figure 1. Location of the Mount Gordon ore bodies, resources and ore reserves

Geology and Mineralisation

Richardson and Moy (1998) recently updated the geology and mineralisation of the Mt Gordon Copper deposits.

The pyrite/chalcocite/chalcopyrite ore bodies at Mammoth, Esperanza and Esperanza South, are localised in brittle breccia and replacement zones associated with a series of interconnected faults. The faults are related to the Mt Gordon Fault, a regional scale NE trending transpressional dextral strike slip system. Movement on the Mt Gordon Fault occurred in the later stages of the Isan Orogeny (1590 – 1500Ma). Brittle quartzites of the Whitworth Quartzite (~1740Ma) host mineralisation at Mammoth. Esperanza and Esperanza South are hosted by carbonaceous shales of the Esperanza Formation (~ 1650Ma).

Despite the contrasting appearance of hypogene mineralisation due to the different hosts, each ore body shows a progression from early silicification to two generations of pyrite and then to introduction of copper species which in part replace pyrite. At Esperanza, sulphides show large-scale replacement of host rocks to form a massive sulphide zone 60 m wide. At Mammoth, sulphide mineralisation is confined to veins and breccia zones but shows some host rock replacement as well. Chlorite, haematite and K feldspar alteration are referred to in the literature on the deposits. These forms of alteration are not well defined and are part of the subject of current PhD research (Clark, in prep.).

The economics of the Mt Gordon Operations are dominated by the occurrence of copper as various leachable species of the chalcocite group. There is strong evidence for a supergene origin for chalcocite in the Esperanza ore body. At Mammoth there is evidence for complex overprinting of hypogene copper sulphides by supergene copper sulphides. Hypogene chalcocite is found to 900 m below surface.

Ar/Ar dating of manganese oxides from the ironstone overlying Esperanza indicate two weathering events at 23Ma to 15Ma and around 3Ma which are related to the supergene enrichment process (Briese, 1998).

Exploration/Development and Production history to 1996

The scope of recent changes at Mt Gordon is better appreciated with an understanding of the exploration/development and production history which is summarised below (see also Brock et al., 1998).

1923 – 1969

The Shah brothers discovered copper and a lease was pegged at Mammoth in 1927. Small operators produced a total of 7000 tonnes copper in high-grade ore from shallow workings on the Mammoth No 1 ore body. There are no workings or production from Esperanza for this period. The Esperanza leases were pegged in 1960s by Morrison and others.

1969 – 1977

First company scale development, initially by VAM, and then by a consortium of Consolidated Goldfields Ltd and Mitsubishi Ltd. They produced a total of 50,000 tonnes of copper by treatment of Mammoth ore to produce a flotation concentrate. Copper in concentrate production ranged from 4000 to 11000 tpa. The Mammoth mine reached 500 m below surface. An exploratory decline to Esperanza in 1972 was abandoned before reaching the ore body. Diamond drilling intersected Mammoth to 600 m, Esperanza to 350 m and Esperanza South to 200 m below surface.

1978 – 1982

Renison Goldfields Consolidated Ltd experimented with heap leaching and in-situ leaching of Mammoth ore to produce copper cement and copper cathode by SXEW, and 4500 tonnes of copper were produced. In 1982 Renison decided not to proceed, sold the plant, and the property was closed.

1983 – 1988

Operation suspended

1989 – 1996

Adelaide Brighton Cement Ltd. purchased the property. They developed an in-situ leach operation in the

Mammoth mine to produce cathode copper through an SX/EW plant rated at 7500 tpa, later expanded to 14,000 tpa. They extended underground development to 600 m below surface (4720RL) for leaching stopes. High operating costs with the in-situ leaching process prompted the establishment of surface heap leaching using Mammoth ore. Operating costs could not be reduced and Adelaide Brighton decided to sell the operation. Total copper production was 44,000 tonnes at an average of 6000 tpa. Drilling at Esperanza and Mammoth continued. E lens was intersected below the Mammoth workings at around 1000 m below surface.

By 1996 the status of the property can be summarised as:

- Mammoth mineralisation was known by drilling to exist to 1000 m below surface and by development to 600 m below surface.

- The Esperanza deposit was known by drilling to exist to 350 m below surface but very poorly defined from surface to 150 m below surface. There was large mineral resource inventory of 16Mt at 4.1% Cu at Mammoth, Esperanza and Esperanza South.

- Ore reserves were only 1.2Mt at 3.6% Cu, all at Mammoth. (Adelaide Brighton Annual Report 1995).

- Copper concentrate production and copper cathode production from in-situ leaching and surface heap leaching, all based on Mammoth ore, had proven uneconomic.

- Total copper production from the whole ore system from 1927 to 1996 was around 100,000 tonnes copper from a resource inventory at 1995 of around 650,000 tonnes copper.

- Production never exceeded 11,000 tonnes copper per year.

Exploration/Development 1996 – 2000

Aberfoyle purchased the Mt Gordon Operation from Adelaide Brighton in June 1996. Western Metals Ltd gained control of the operation by takeover of Aberfoyle in 1998. There was an urgent need to increase reserves so that copper output could be lifted from the low levels, which had contributed to previous uneconomic production. Drilling commenced immediately.

At Esperanza previous owners had defined a chalcocite resource of 3.3Mt at 6.2% Cu (Adelaide Brighton Annual Report 1995). The resource was poorly defined from surface down to 150 m (5150RL) due to very bad drilling conditions in what now is interpreted as a supergene leached silica cap. The ore zone shape was interpreted as a 20 m zone parallel to the Mammoth Extended Fault from 5200RL to 4950RL. Underground mining would be necessary for this zone. The 1972 exploration adit indicated bad ground conditions and high water flows around the ore zone.

Aberfoyle commenced testing the upper 150 m of Esperanza. After overcoming atrocious drilling conditions in the chert cap the first holes returned spectacular chalcocite intersections over a much wider zone than expected including:

SD279 65.7m at 12.2% Cu

SD280 49.5m at 9.5% Cu

Previous drilling was abandoned in the silica cap metres short of this mineralisation. Subsequent drilling defined a total chalcocite ore reserve of 4.2Mt at 7.1% Cu located above 5100RL (Aberfoyle Annual Report 1997).

This drilling program transformed the potential of the project. It:

- defined a reserve of 300,000 tonnes of leachable copper at high grade;

- showed that the bulk of the mineralisation was shallower than previously interpreted;

- allowed for extraction by open cut with better recovery than would have been possible with the anticipated bad ground conditions in an underground operation.

While drilling was underway at Esperanza, re-evaluation and digitizing of the drilling database were undertaken to better visualize the complex geometry of the entire ore system and define new exploration targets. An untested inflexion in the Mammoth Fault was selected as a potential dilational zone. Drilling discovered Mammoth 2 Lens, which has an inferred resource of 1.1Mt at 5.8% Cu as chalcocite (WMT Dec 1998 quarterly SER). This lens is in a position and orientation previously unexpected for the Mammoth mine.

The following table compares the changes to resources and reserves since 1995 for the complete ore system:

| Cu metal in resources | Cu metal in reserves | |

| Adelaide Brighton 1995 Annual Report | 652,000 tonnes | 43,200 tonnes |

| Western Metals Dec 1999 Reserve Statement | 900,000 tonnes | 358,000 tonnes |

Production 1996 – 2000

From acquisition in 1996 a number of processing routes were assessed to increase production and produce copper metal using the existing SXEW plant. These included leaching, flotation and tank leaching by ferric sulphate, and bacterial methods (Brock et al., 1998; Richmond, 1998).

Following the discovery of the high-grade mineralisation at Esperanza it was clear that a high recovery process was required and that, with an open cut now possible, production could be significantly expanded. A low-pressure temperature autoclave was designed by the company’s metallurgical group for the leaching stage. Pilot plant trials showed recoveries over 90% with residence times of four hours. The SX/EW was expanded to 45,000 tpa of LME A grade copper. The use of an autoclave treatment for copper sulphide ore coupled with SX/EW is a world first.

Construction was completed in late 1998. In 1999, as the plant was brought on line, 32,133 tonnes cathode copper were produced at a cash cost of US43.9 cents/lb. The target for 2000 is production of 44,000 tonnes at 91% recovery and cash cost of US35 cents/lb. The last year of production of the previous plant was 7832 tonnes of copper cathode at a cash cost of $US1.06/lb. (Brock et al., 1998).

Conclusions

From the 1970s, when company scale operations began at Mt Gordon, the mine has never realised its potential.

With a review of existing data, and persistence in very bad drilling conditions, the current owners were able to dramatically increase reserves and allow planning of an open cut operation on a high grade orebody at Esperanza.

The company was able to take full advantage of this success by developing in house a novel processing system which maximises recovery, minimises leach times, and produces high grade copper metal on site. This combination places Mt Gordon in the lower cost quartile of copper producers.

Exploration is continuing to prolong the life of the operation.

References

Briese, M.L., 1998. Supergene Copper Ore and Regolith Genesis, Esperanza Mine, Gunpowder, Northwest Queensland. Unpublished BSc Honours Thesis, University of Queensland.

Brock, J.G., Chomley, J.C. and Richmond, G.D., 1998. Copper Leaching at Gunpowder. Conference Proceedings, AusIMM ’98 – the Mining Cycle. The Australian Institute of Mining and Metallurgy, Melbourne:281-284.

Clark, D., in prep. Geology, Geochemistry and Genesis of the Gunpowder Cu Deposit, Queensland. PhD thesis in preparation, University of Tasmania.

Richardson, S.M. and Moy, A.D., 1998. Gunpowder Copper Deposits. In: Geology of Australian and Papua New Guinean Mineral Deposits, Eds: D.A Berkman and D.H. Mackenzie. The Australian institute of Mining and Metallurgy, Melbourne:743-752.

Richmond, G.D., 1998. Novel Hydrometallurgical Process at Mount Gordon. Australian Journal of Mining Conference, Adding Value to the Carpentaria Mineral Province. Mt Isa, 1998.

Received: March 2000

Published: Jan 2001

AIG Journal Paper 2001-02, Jan 2001